- Subscribe

-

Get email updates on new products

- Contact Us

-

Shandong Welldone Environmental New Materials Co.,Ltd..

Contacts: Jack Ma

Phone: +86-17664031716

E-mail: info@welldonechina.com

Website: www.polyacrylamidechina.com Contact Now

- High Rated Products

- News

-

-

olyacrylamide: an efficient and safe industrial additive

As a high molecular polymer, polyacrylamide (PAM) plays an important role in many industrial fields such as water treatment, oil extraction, and papermaking. -

How to clean if polyacrylamide accidentally got on clothes?

Our technicians do experiments almost every day. During the operation, the polyacrylamide flocculant may accidentally get on the clothes. How to clean... -

The important role of polyacrylamide

The important role of polyacrylamide -

Marsh Funnel Viscosity Test

Product:WD-7161 Test conditions:solution 0.1%,stirred at 600 RPM for 1 hour,temperature 22℃ Marsh Funnel Viscosity:381 seconds Shandong Welldone Env... -

Flocculant - China Polyacrylamide (PAM) Supplier

Polyacrylamide PAM, a new material cellulose dedicated to sewage treatment. -

The Festival Laba en China

On January 10, it was festival Laba in China. It is the eighth day of the twelfth lunar month and is considered as a prelude to the Spring Festival, C... -

Facebook admits mistakes but no apology

On Wednesday, Facebook CEO Mark Zuckerberg finally broke his silence, responding to the company's recent troubles. According to CNBC, Zuckerberg poste... -

Application of PAM in sewage treatment

Polyacrylamide is a widely used chemicaladditive, it can treat many types of sewage.For the following types of sewage,the correct use of polyacrylamid... -

The US Foiled a Terrorist Plot against San Francisco during Christmas

US Foiled a Terrorist Plot against San Francisco during Christmas,The suspect Everett Alan Jameson was a truck driver who served in the U. S. Marine Corps, China Top 10 manufacturer of Polyacrylamide -

Comprehensive knowledge of anionic polyacrylamide

Comprehensive knowledge of anionic polyacrylamide

-

Oil drilling grade carboxy methyl cellulose CMC

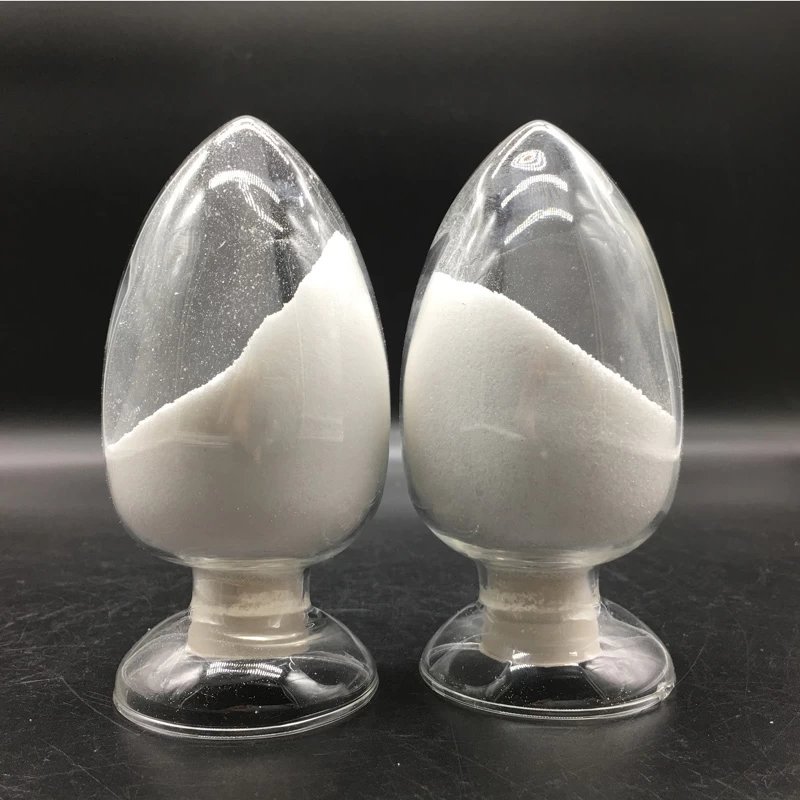

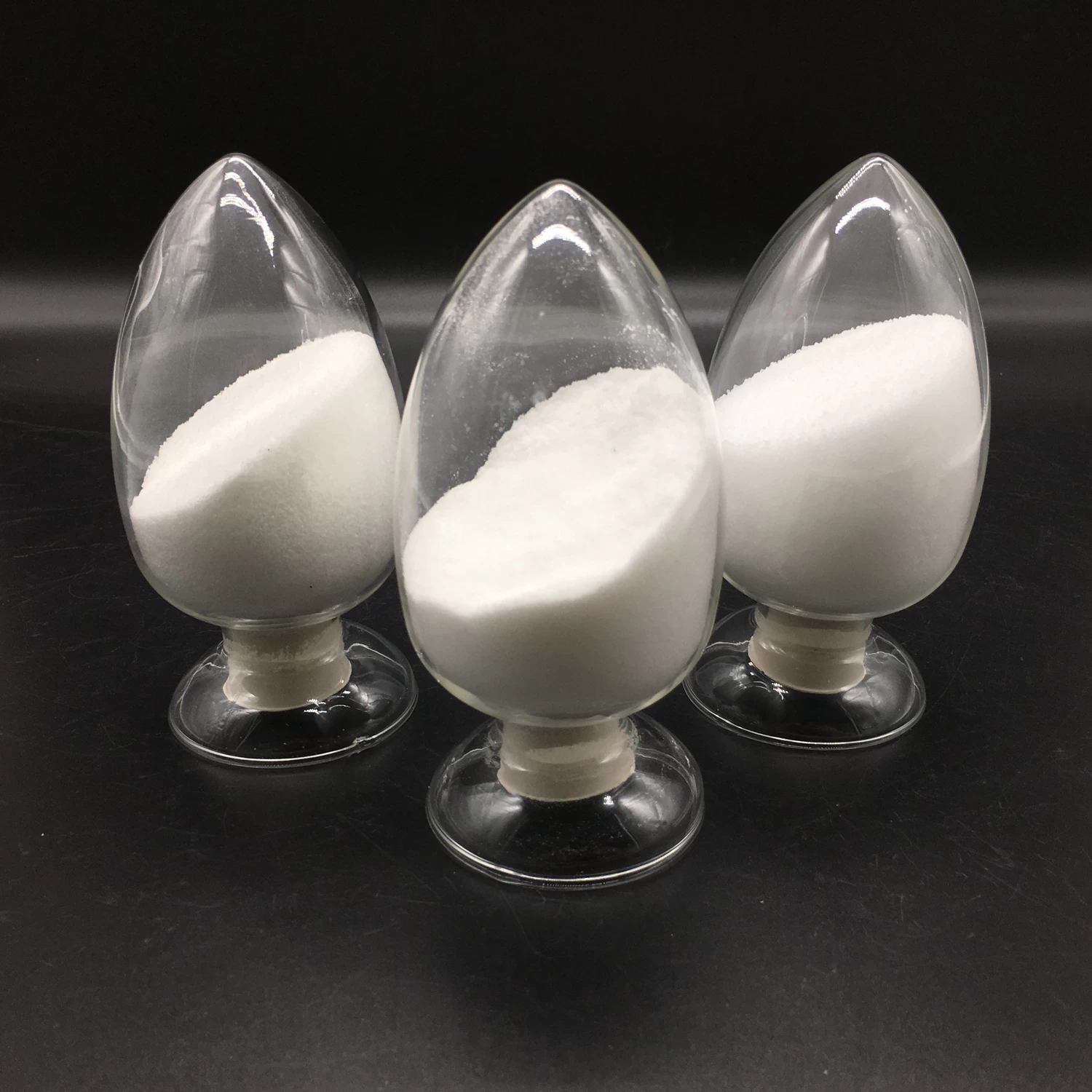

- Appearance: White or light yellow powder, no lumps

- Application: oil drilling

- Moisture: ≤10

- Purity: ≥80

- Degree of substitution/D.S: ≥0.8

- PH:6.5-8

- Apparent viscosity/m Pa.s:30-90

- Filter loss/mL:≤10

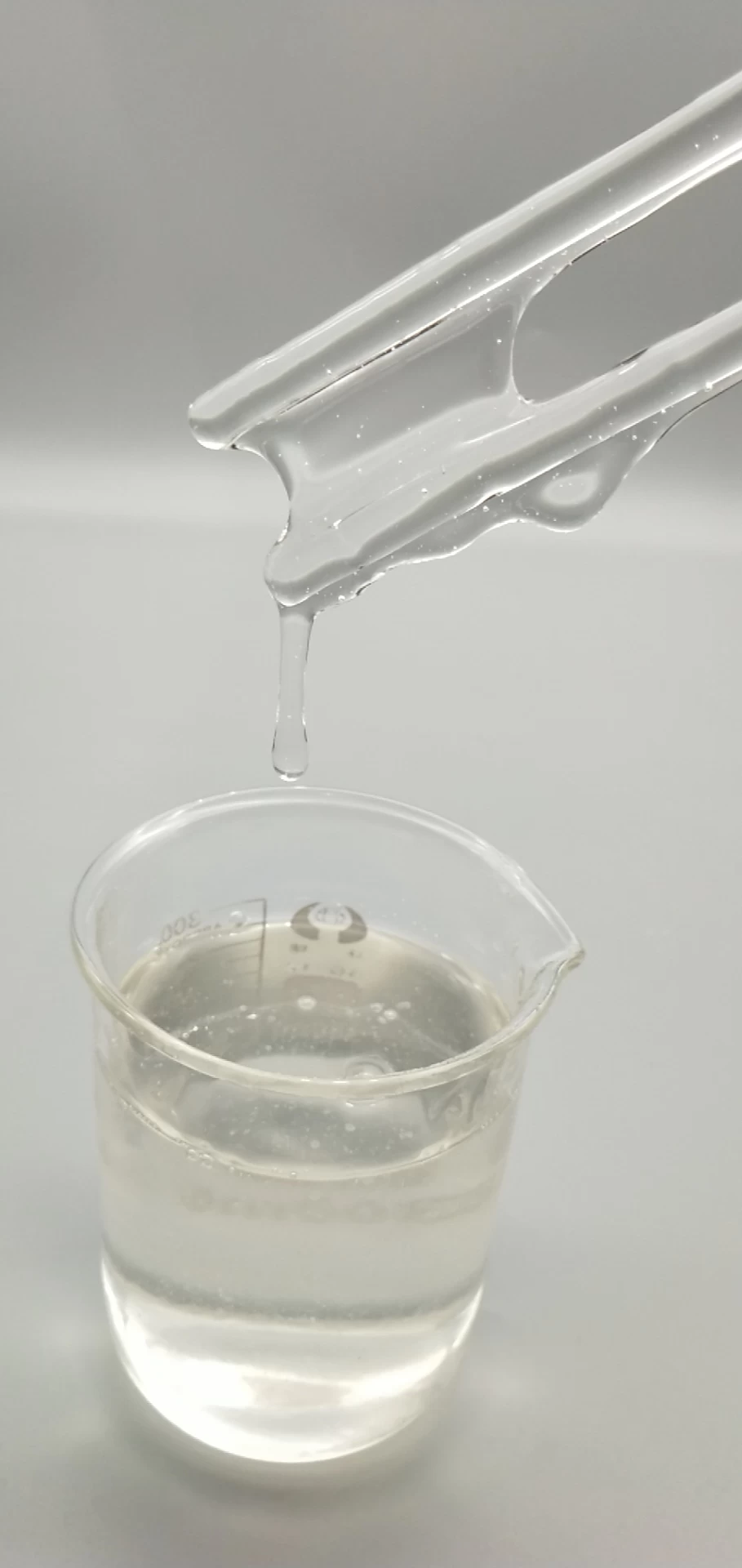

CMC appears to be white or light yellow powder, which is odorless and non-toxic. it's soluble in cold or hot water. when it solutes, some colloidal solution will appear, which is neutral or slightly alkaline. The important feature of CMC is that it can form colloid solution with high viscosity. Many factors influencing its viscosity are concentration, PH, temperature, substituted ratio and salts, etc.

CMC, as a kind of water-soluable gel in the drilling fluid system, constitutes drilling mud. It's with high control ability of water loss. HV2 is a highly efficient fluid loss agent. When under the lower amount of water, you can control the water loss in a appropriate water level, without affecting the other performance of the mud. In addition, the quality of the mud cake it formates is good and it's with strong and tough property. Besides, its performance of salt resistance and temperature resistant is good. Under a certain concentration of salt, it can still have good filtration reduction ability and keep a certain rheology. its viscosity changes little in the saline solution and aqueous solution. Adhesive is applicable for deep drilling. The rheology of slurry, with performance of good non-newtonian fluid, can be easily controlled. when CMC was used as cementing fluid, it can prevent fluid from flowing into the rock formation and fracture. As a fracturing fluid, it can control the loss of fluid that flows into the well.Oil drilling grade carboxy methyl cellulose CMCOil drilling grade carboxy methyl cellulose CMCOil drilling grade carboxy methyl cellulose CMCOil drilling grade carboxy methyl cellulose CMCOil drilling grade carboxy methyl cellulose CMCOil drilling grade carboxy methyl cellulose CMC

The basis for the determination of the stirring time is that when the CMC is uniformly dispersed in the water and there are no apparent large agglomerate-like objects, the stirring can be stopped and the CMC and the water are allowed to penetrate and fuse with each other in a standing state.

The basis for determining the time required for complete dissolution of the CMC is as follows:

(1) There is no solid-liquid separation between the CMC and the water.

(2) The mixed paste has a uniform and uniform surface with smooth surface;

(3) The color of the mixed paste is nearly colorless and transparent, and there is no granular object in the paste. The CMC is introduced into the batching tank and mixed with water, until the CMC is completely dissolved, and the time required is between 10 and 20 hours.

Tel:+86-17664031716

Contact Person:Jack Ma

PDF Show:PDF

E-mail:info@welldonechina.com

E-mail:info@welldonechina.com +86-17664031716

+86-17664031716

-for-drilling-muds.png.webp)