- Subscribe

-

Get email updates on new products

- Contact Us

-

Shandong Welldone Environmental New Materials Co.,Ltd..

Contacts: Jack Ma

Phone: +86-17664031716

E-mail: info@welldonechina.com

Website: www.polyacrylamidechina.com Contact Now

- High Rated Products

- News

-

-

olyacrylamide: an efficient and safe industrial additive

As a high molecular polymer, polyacrylamide (PAM) plays an important role in many industrial fields such as water treatment, oil extraction, and papermaking. -

How to clean if polyacrylamide accidentally got on clothes?

Our technicians do experiments almost every day. During the operation, the polyacrylamide flocculant may accidentally get on the clothes. How to clean... -

The important role of polyacrylamide

The important role of polyacrylamide -

Marsh Funnel Viscosity Test

Product:WD-7161 Test conditions:solution 0.1%,stirred at 600 RPM for 1 hour,temperature 22℃ Marsh Funnel Viscosity:381 seconds Shandong Welldone Env... -

Flocculant - China Polyacrylamide (PAM) Supplier

Polyacrylamide PAM, a new material cellulose dedicated to sewage treatment. -

The Festival Laba en China

On January 10, it was festival Laba in China. It is the eighth day of the twelfth lunar month and is considered as a prelude to the Spring Festival, C... -

Facebook admits mistakes but no apology

On Wednesday, Facebook CEO Mark Zuckerberg finally broke his silence, responding to the company's recent troubles. According to CNBC, Zuckerberg poste... -

Application of PAM in sewage treatment

Polyacrylamide is a widely used chemicaladditive, it can treat many types of sewage.For the following types of sewage,the correct use of polyacrylamid... -

The US Foiled a Terrorist Plot against San Francisco during Christmas

US Foiled a Terrorist Plot against San Francisco during Christmas,The suspect Everett Alan Jameson was a truck driver who served in the U. S. Marine Corps, China Top 10 manufacturer of Polyacrylamide -

Comprehensive knowledge of anionic polyacrylamide

Comprehensive knowledge of anionic polyacrylamide

-

Super Agarbatti binder

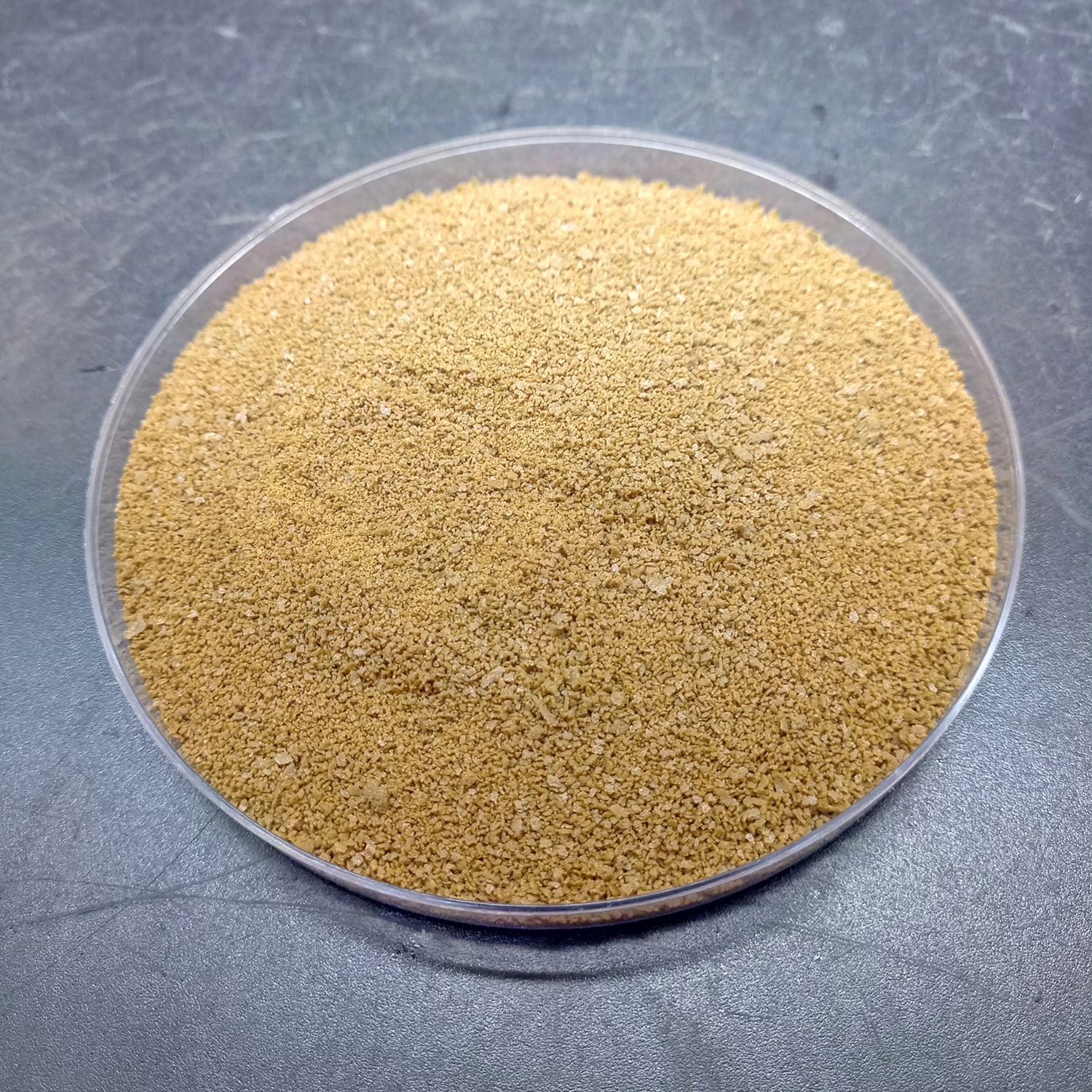

- 1.Molecular weight: 8-35 million

- 2.Degree of hydrolysis: 15%-40%

- 3.Solid content: >90%

- 4.Mixing time: < 15 minutes

- 5.Company Viscosity (0.1% solution): 1000-4000

Features:

Specifications:

SAB is a super replacement of traditional joss powder, it features with very high viscosity, environmental friendly, easy control and very low costs.

SAB is widely used in machine made and hand made incense stick, with the correct mixing rate, can save more than 50% production costs.

Specifications:

| Appearance: | White/Grey Granule Powder |

| Ionic Charge: | Anionic |

| Molecular Weight: | 8-35 Million |

| Granule: | 20-60 mesh |

| Solid Content: | ≥90% |

| Hydrolysis Degree: | 15%-40% |

| Mixing Time: | ≤15 minutes |

| Company Viscosity

(0.1% solution): |

1000-4000 |

Application:

1.Machine made incense stick

1.Machine made incense stick

Weight SAB with raw material (wood powder, charcoal,etc.) with rate of 1:25-50, mixing them after water for 15 minutes, then put them inside the machine for production.Try 2-5 times to get the best mixing rate and product costs.

2.Hand made incense stick

Weight SAB with raw material (wood powder, charcoal,etc.) with rate of 1:25-40, mixing them after water for 15 minutes, then do the production. For hand made incense stick, customers should use medium viscosity SAB for production, because it is too sticky.Try 2-5 times to get the best mixing rate and product costs.

Tag:

coagulant

,water treatment

,flocculant

,Polyacrylamide

,Cationic polyacrylamide for dewatering

,PHPA for drilling muds

,PHPA for EOR

,PHPA with API standard

,Polyacrylamide for drilling muds

,Polyacrylamide for EOR

,Polyacrylamide with API standard

,Anionic polyacrylamide

,Polyacrylamide for EOR

,Polyacrylamide with API standard

,Anionic polyacrylamide

Shandong Welldone Environmental New Materials Co.,Ltd.

Tel:+86-17664031716

Contact Person:Jack Ma

PDF Show:PDF

E-mail:info@welldonechina.com

E-mail:info@welldonechina.com +86-17664031716

+86-17664031716

-for-drilling-muds.png.webp)