Anionic polyacrylamide Apam index

Anionic polyacrylamide Apam index

|

Molecular weight(million) |

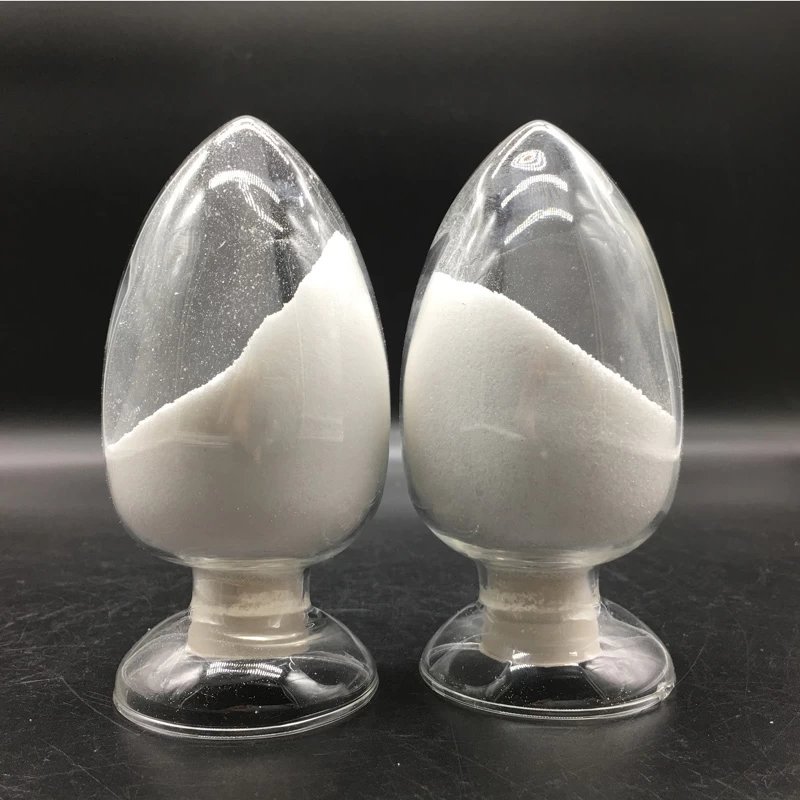

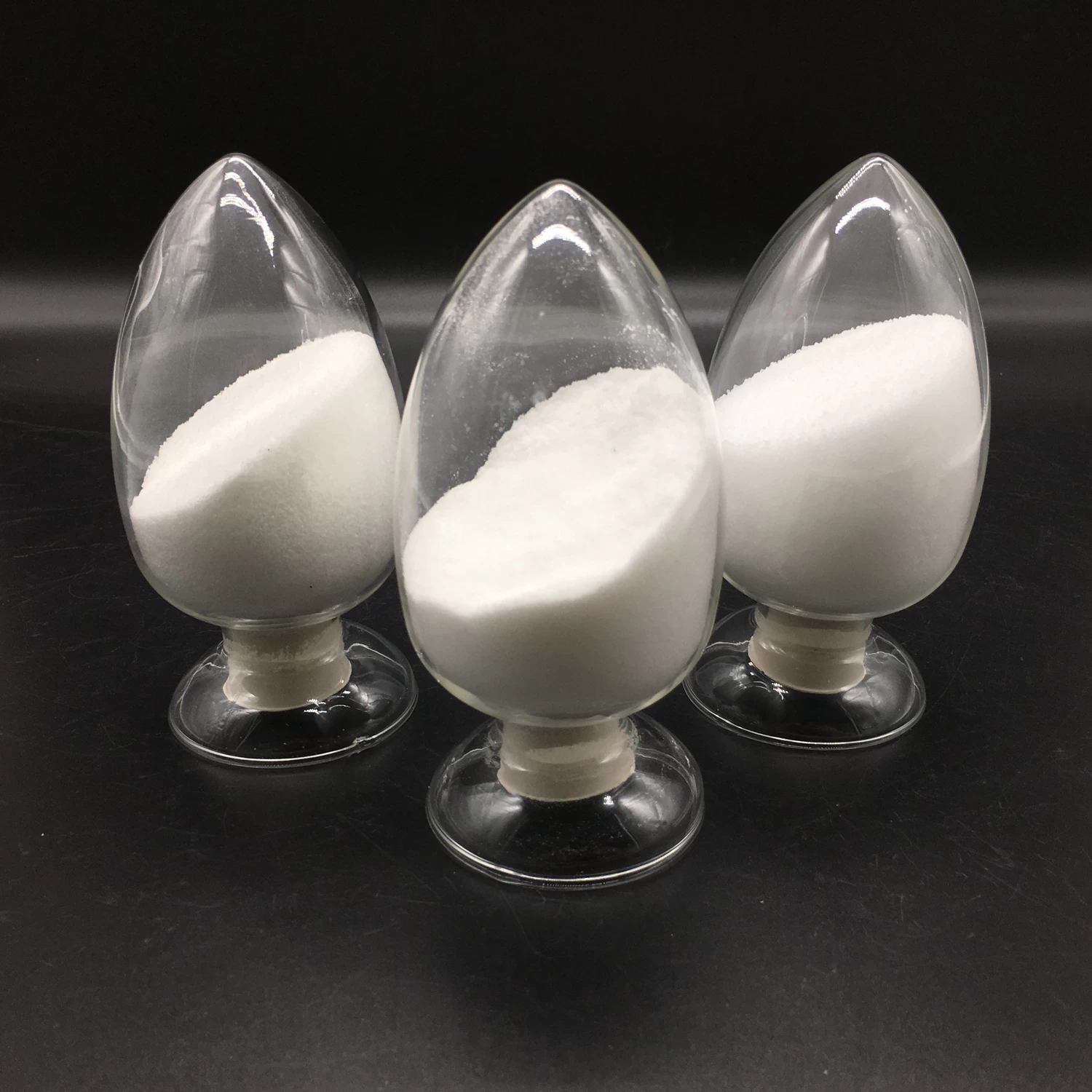

Appearance |

Water solubility % |

PH application range |

Solid content % |

Solution rate Min |

Residual monomer content % |

|

10-12 |

White particle powder |

10-15 |

5-14 |

≥89 |

≤60 |

≤0.05 |

|

14-16 |

White particle powder |

25-30 |

5-14 |

≥89 |

≤60 |

≤0.05 |

|

15-18 |

White particle powder |

25-30 |

5-14 |

≥89 |

≤60 |

≤0.05 |

|

17-20 |

White particle powder |

25-30 |

5-14 |

≥89 |

≤60 |

≤0.05 |

|

20-30 |

White particle powder |

22-30 |

5-14 |

≥89 |

≤60 |

≤0.05 |

precautionsfor product selection:

1.theselection of flocculant must fully consider the requirements of process andequipment.

2.thestrength of floc can be improved by increasing the molecular weight offlocculant.

3.thecharge value of flocculant must be selected by experiment. Climatechange (temperature) affects the selection of flocculant.

4.themolecular weight of the flocculant shall be selected according to the floc sizerequired by the treatment process.

5.the flocculant must be fully mixed anddissolved with the sludge before treatment

Performance characteristics:

1. There arepositive genes in polyacrylamide molecule, which has strong flocculatingability, low dosage and obvious treatment effect.

2. It has good solubility andhigh activity. The alum flower formed by condensation in water body is large,settling is fast, and its purification capacity is 2-3 times larger than thatof other polymers.

3. Strong adaptability is little affected by pH value andtemperature of water body. After purification of raw water, it reaches thenational standard for drinking water. After treatment, the suspended particlesin the water reach the purpose of flocculation and clarification, which isconducive to ion exchange treatment and preparation of high-purity water.

4. Itis less corrosive and easy to operate, which can improve the labor intensityand working conditions of the dosing process.

E-mail:info@welldonechina.com

E-mail:info@welldonechina.com +86-17664031716

+86-17664031716

-for-drilling-muds.png.webp)