PHPA for ENHANCED OIL RECOVERY

Choosing the right product technology and application strategy for each individual reservoir is extremely important in maximizing oil recovery. WELLDONE has gained considerable knowledge since 1998 from its experience working with petroleum industry on EOR projects. We use our expertise and on site experience to help our customers evaluate the reservoir characters to design the cost-effective development programs.

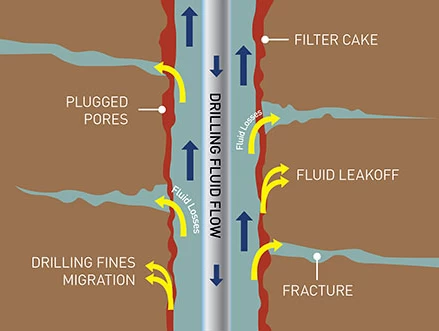

Polymer flooding is the injection of long-chain polymer molecules dissolved in water to increase the viscosity of injected water. This method improves the oil-water mobility ratio, vertical and areal sweep efficiency. The polymer causes a reduction in the permeability and propagation through high-permeability zones in the reservoir ensuring water diversion to lower permeability zones. This lowers flow velocity and increases the sweep area to increase oil recovery.

|

Product lines |

Characteristics |

|

WELLDONEPAM Ⅰ |

This line use for enhanced oil recovery in reservoirs with moderate salinity and temperatures. Linear HPAM |

|

WELLDONEPAM Ⅱ |

This line suitable for reservoirs with medium salinity and temperature. Linear HPAM with AMPS |

|

WELLDONEPAM Ⅲ |

This Line is designed for high-salinity and high-temperature reservoirs. Linear Terpolymer. |

|

WELLDONE OFFSHORE POLYMER |

The products of this line are designed for offshore polymer flooding. They dissolve quickly in sea and high-salinity produced water, salinity and temperature-resistant and require minimal facilities. |

WELLDONEPAM III SERIES-SALINITY AND TEMPERATURE RESISTANT POLYMERS

Polymer flooding is one of the most common and effective methods of EOR methods. Until recent time, there were no cost-effective polymers for high-salinity and high-temperature reservoirs. Large number of oil reservoirs throughout the world have low oil recovery factors and being potential target forpolymer flooding are characterized by harsh conditions-elevated salinity and temperature. WELLDONE introduced its WELLDONEMUD®ll series to provide high-performing polymers for EOR projects where produced water is used for injection and with high salinity and temperatures reservoir conditions.

Main requirements for EOR polymer:

1) Dissolve completely in injection water within a short period of time, in order to eliminate injectivity problems and minimize surface facility investment.

2) Maintain target apparent viscosity over time under reservoir high-temperature and high-salinity conditions to maximize sweep efficiency, minimize severe permeability reduction and additional water treatment caused by precipitation of polymers.

Summary of WELLDONE polymers' characteristics

1. WELLDONEMUD® polymers have no hydrophobic monomers incorporated that cause associative behavior. Therefore, they have minimal adsorption and do not bring injectivity issues.

2. WELLDONEMUD® will dissolve in produced water directly within required time. This minimizes surface facility requirements and eliminates injectivity problem caused by in complete dissolution.

3. WELLDONEMUD® will maintain higher viscosity at high temperatures and salinity conditions. Different products will be recommended according to customers' requirements for long term stability to ensure maximized technical success and optimal chemical cost for polymer flooding project.

4. WELLDONEMUD® series is the leading temperature and salinity resistant EOR polymer type offered on the market to date.

SERVICES

WELLDONE designs, develops and provides chemical enhanced oil recovery(CEOR)technologies that increase the field development effectiveness and improve oil recovery. WELLDONE Chemicals technologies have been successfully applied in some of the most challenging reservoir conditions across the globe. For instance, polymer flooding applications resulted in an additional production of 50-120 tons of oil per ton of polymer applied.

WELLDONE provides services to evaluate CEOR opportunities forthe target reservoir and to select the best technology. Our polymer solutions can be tailored according to specific reservoir conditions. The facilities engineering design is the field-and location-specific.

WELLDONE has dedicated significant resources to R&D program since 1998. WELLDONE has the technical support team existing for more than 20 years; its team members possess strong knowledge and experience in polymer flooding and conformance control techniques and implementation. Additionally, WELLDONE has certified laboratory for EOR analysis. Further,we partner in joint R&D programs with academic institutions. For instance, with Chinese Academy of Sciences we successfully collaborated on technologies development and commercialization including offshore polymer flooding technology.

WELLDONE have over 70 units of analytical testing equipment: AXP work station, Sun work station, Micro EOR laboratory, RS-75 rheometer, long core flood test facility, Hitachi Z-5000 atomic absorption spectroscopy equipment, Brookfield viscometer, loopline for offshore polymer testing operations. We also possess specialized software required for experimentation, chemistry, field static and dynamic modeling, facilities control.

SERVICES

With over 30 staff members working in the R&D department, WELLDONE allocates 4%of its annual sales to the development and deployment of new products, facilities as well as to the improvement of current products and facilities.

Our R&D center collaborates with Chinese Academy of Sciences, working on and commercializing several leading technologies successfully including offshore polymer flooding technology.

Our R&D department supports the followings research activities on daily basis:

Products selection/application:

1. Evaluation together with customers so the most suitable products are selected to obtain the maximum investment return:

|

Polymer evaluation and selection criteria for EOR application |

||

|

Molecular weight |

Apparent and real viscosity |

Hydrolysis degree |

|

Core flooding test |

Filtration and screen factor test |

Dissolution time |

|

Long term stability |

Injectivity test |

Adsorption test |

|

Other polymer rheology tests |

||

2. Develop customer specific solutions to ensure the cost-effective program is developed:

|

Project evaluation |

Reservoir feasibility |

|

Pilot test |

Optimize polymer selection |

|

Full field implementation |

Experimental program |

3. Polymer product performance improvement as ongoing R&D work for existing customers with the following characteristics:

|

Viscosity development |

Temperature resistance |

|

Shear resistance |

Salinity resistance |

|

Dissolution ability |

Better compatibility with reservoir fluids |

|

Recovery efficiency |

Cost reduction |

|

Improving long-term and thermal stability |

|

Introducing viscous polymer solutions to the flooding process, the efficiency of the volumetric sweep increases, reducing water channeling and break through. These effects result in improved oil recovery.

WELLDONE different polymer technologies offer our customer the very effective and economically attractive development option for their fields. Please refer to EOR section for more information on WELLDONEPAM product lines for EOR application.

E-mail:info@welldonechina.com

E-mail:info@welldonechina.com +86-17664031716

+86-17664031716

-for-drilling-muds.png.webp)