- Subscribe

-

Get email updates on new products

- Contact Us

-

Shandong Welldone Environmental New Materials Co.,Ltd..

Contacts: Jack Ma

Phone: +86-17664031716

E-mail: info@welldonechina.com

Website: www.polyacrylamidechina.com Contact Now

- High Rated Products

- News

-

-

How to clean if polyacrylamide accidentally got on clothes?

Our technicians do experiments almost every day. During the operation, the polyacrylamide flocculant may accidentally get on the clothes. How to clean... -

olyacrylamide: an efficient and safe industrial additive

As a high molecular polymer, polyacrylamide (PAM) plays an important role in many industrial fields such as water treatment, oil extraction, and papermaking. -

The important role of polyacrylamide

The important role of polyacrylamide -

The Festival Laba en China

On January 10, it was festival Laba in China. It is the eighth day of the twelfth lunar month and is considered as a prelude to the Spring Festival, C... -

Flocculant - China Polyacrylamide (PAM) Supplier

Polyacrylamide PAM, a new material cellulose dedicated to sewage treatment. -

Marsh Funnel Viscosity Test

Product:WD-7161 Test conditions:solution 0.1%,stirred at 600 RPM for 1 hour,temperature 22℃ Marsh Funnel Viscosity:381 seconds Shandong Welldone Env... -

Facebook admits mistakes but no apology

On Wednesday, Facebook CEO Mark Zuckerberg finally broke his silence, responding to the company's recent troubles. According to CNBC, Zuckerberg poste... -

The US Foiled a Terrorist Plot against San Francisco during Christmas

US Foiled a Terrorist Plot against San Francisco during Christmas,The suspect Everett Alan Jameson was a truck driver who served in the U. S. Marine Corps, China Top 10 manufacturer of Polyacrylamide -

Application of PAM in sewage treatment

Polyacrylamide is a widely used chemicaladditive, it can treat many types of sewage.For the following types of sewage,the correct use of polyacrylamid... -

Comprehensive knowledge of anionic polyacrylamide

Comprehensive knowledge of anionic polyacrylamide

-

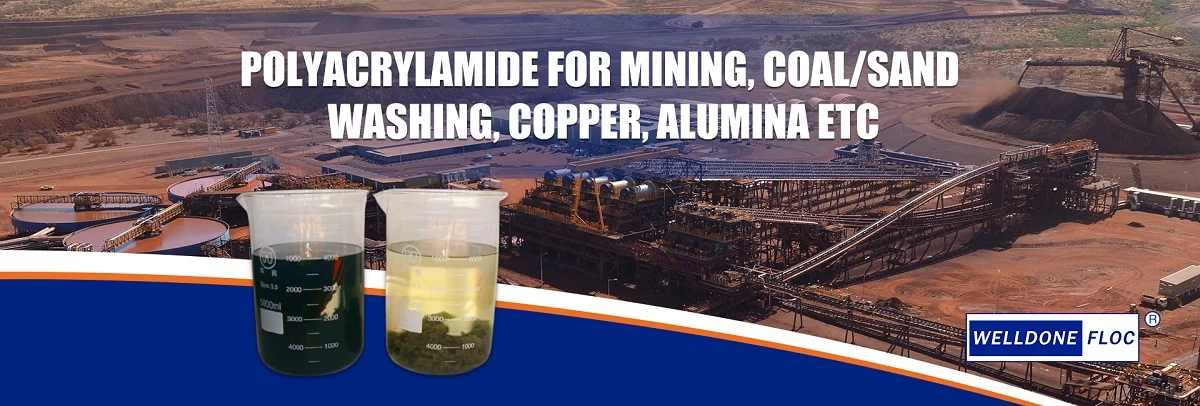

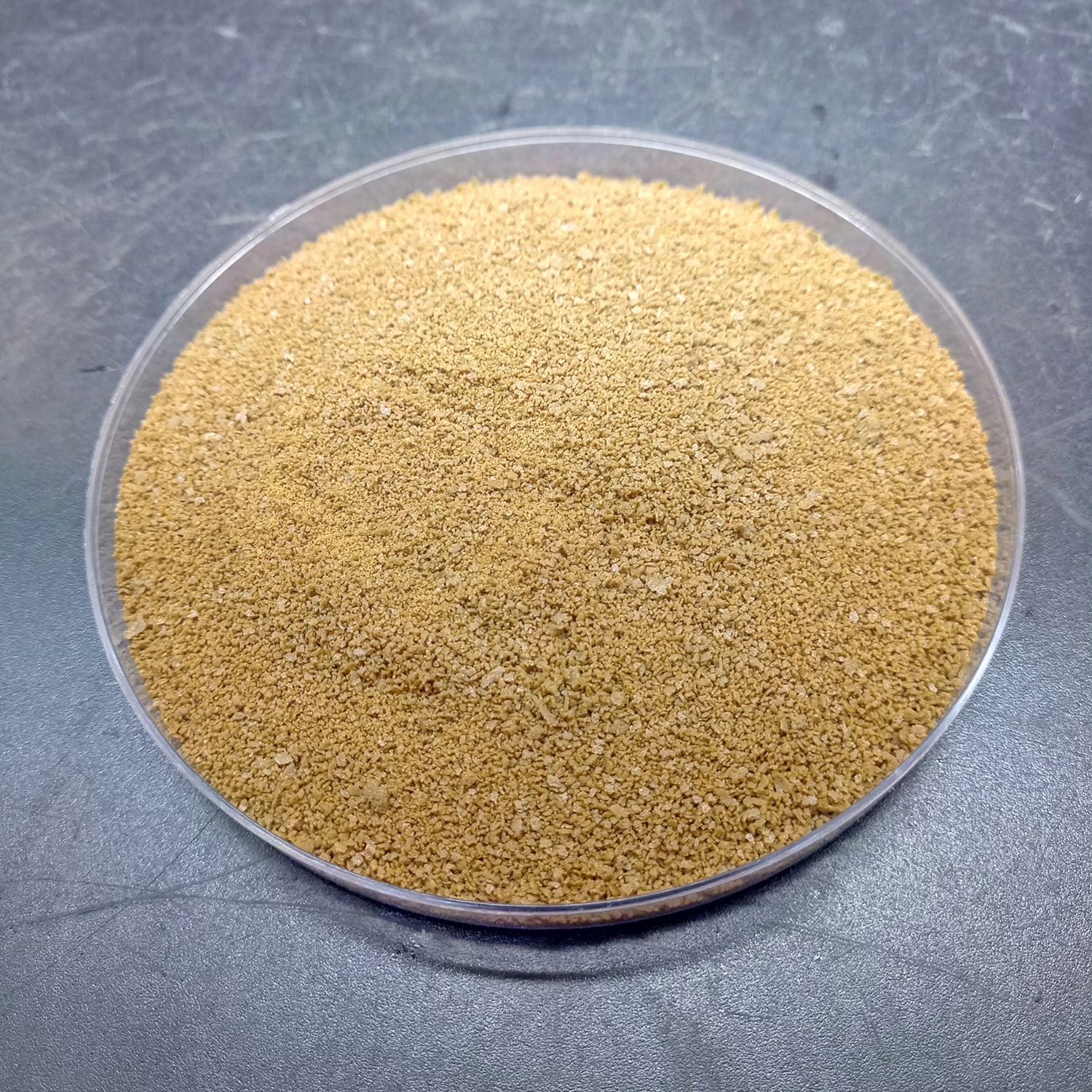

Polyacrylamide for Copper

- 1. Sedimentation of the Copper Concentrate/ Flotation Tailings:

- Match Item No.: A161, A164, A174, A176

- 2. Filtration Aid of the Thickened Tailings/Thickened Copper Concentrate.

- Match Item No.: A164, A174, A176

The ore is crushed and ground to separate the copper-bearing mineral from the wasted materials or gangue. The separated ores will be further crushed by ball mills. The final material particle size will be less than 100 microns.

During the final milling collectors are added to the slurry which preferentially absorb the copper sulphide and make the sulphide particles hydrophobic. These copper minerals are then concentrated by flotation when air bubbles are pumped into the slurry. Frother is normally added to the slurry to stabilize the copper particle to be loaded in bubbles at the top of the slurry when creating froth. The slurry or tailings from the flotation lagoons will be delivered to thickener where flocculants are added to promote rapid sedimentation and generation of a clear overflow, which returns to the process water circuit. The thickened tailings are normally further dewatered by filtration where a flocculant is added as a filtration aid.

The copper laden froth (copper concentrate) is removed from the overflow by mechanical means and is then thickened and dewatered where flocculants are used to improve the sedimentation and filtration rates. The resultant concentrate or cake contains approximately 25 to 35% copper, which is then recovered by pyrometallurgical processing.

|

Grade |

Ionicity |

Molecular Weight |

Ion Charge Density |

Application |

|

A161 |

Anion |

Medium-High |

Low |

A |

|

A164 |

Anion |

Medium-High |

Medium |

A, B |

|

A174 |

Anion |

High |

Medium |

A, B |

|

A176 |

Anion |

High |

Medium-High |

A, B |

A: Sedimentation of the copper concentrate/ flotation tailings.

B: Filtration aid of the thickened tailings/thickened copper concentrate.

Tel:+86-17664031716

Contact Person:Jack Ma

PDF Show:PDF

E-mail:info@welldonechina.com

E-mail:info@welldonechina.com +86-17664031716

+86-17664031716

-for-drilling-muds.png.webp)